2021 - DBM Rio All Rights Reserved

Case study 2 - Scaffolding vs. Industrial Climbing

28/02/2021

Case study 2 - Scaffolding vs. Industrial Climbing

28/02/2021

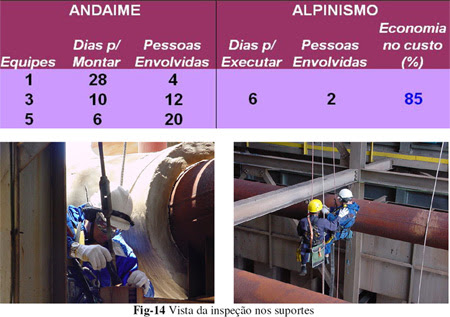

A second comparative study, to understand the advantages of using industrial climbing, in relation to the assembly of scaffolding, was carried out by the technical team of ROPE STEEL. In this case, the operation was an inspection on 29 twinned spring supports (G), installed at a height of 10 meters each. Industrial mountaineering was used to access the supports, which generated savings of 85% compared to the cost of scaffolding.

It is worth remembering that the number of employees to assemble the scaffold would be greater, which would increase exposure to accidents, both for people and for materials, in addition to the increase in operating costs.

In the table below, there are the quantitative data of the number of staff, days and people needed to carry out the inspection, please note:

Specialist in inspection, installation, repair and maintenance of equipment, using rope access techniques and industrial climbing and drones.